Coal in the cement industry

The cement clinker is ground with about 5% gypsum Other materials like slag, fly ash, ash of coal etc may also be added in required proportion to get the final cement powder The main fuel used for firing preheater cyclone and rotary kiln is coal Therefore, coal plays an important role in the manufacturing process of cement Based on the The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the most common solution for cement plants Equipped with the highefficiency RAKM dynamic separator, the ATOX coal mill will grind any type of coal to the requiredATOX coal mill • Execution of coal mill separator modification • Technical key figures: coal mill capacity 20 tph, preheater exhaust gas temperature 360 °C, fine coal moisture max 20 % • Planning of a rice husk and tyre chip feeding facility to substitute 14 % of the primary fuelPROFESSIONAL CEMENT PLANT OPTIMIZATION, cement plant,ball mill,vertical mill,rotary kiln,slag grinding CHAENG specializes in manufacturing tube mills, rotary kiln, vertical mill and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines Rotary kiln shell Steel Slag Vertical Mill Coal vertical mill Raw material Get pricevertical cement mill pdf coal russiacoal mill in sagar cement plant pdf ATOX coal mill The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the most common solution for cement plantscoal mill in sagar cement plant pdf visueelvertalerbe

ROTARY SHAFT OIL SEALS FOR CEMENT AND COAL MILL

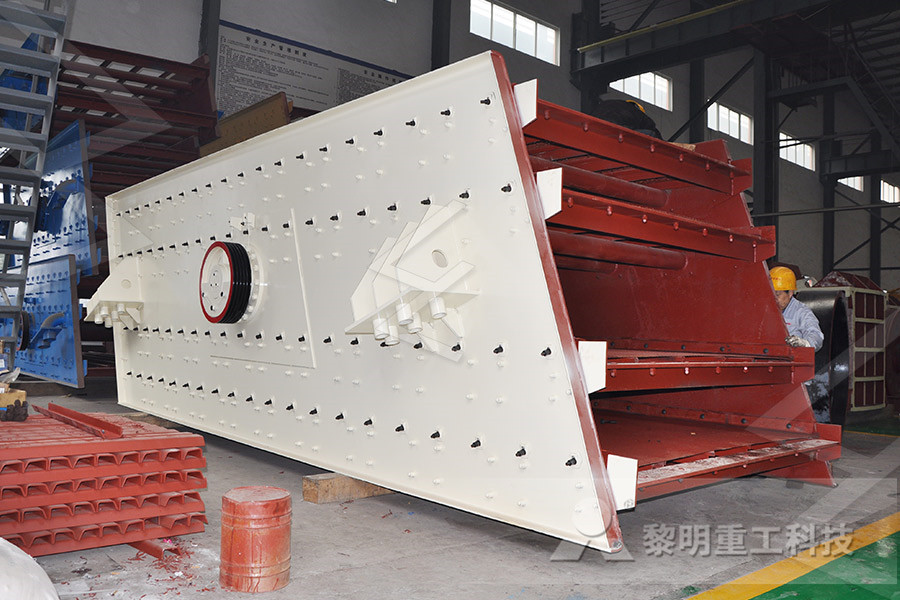

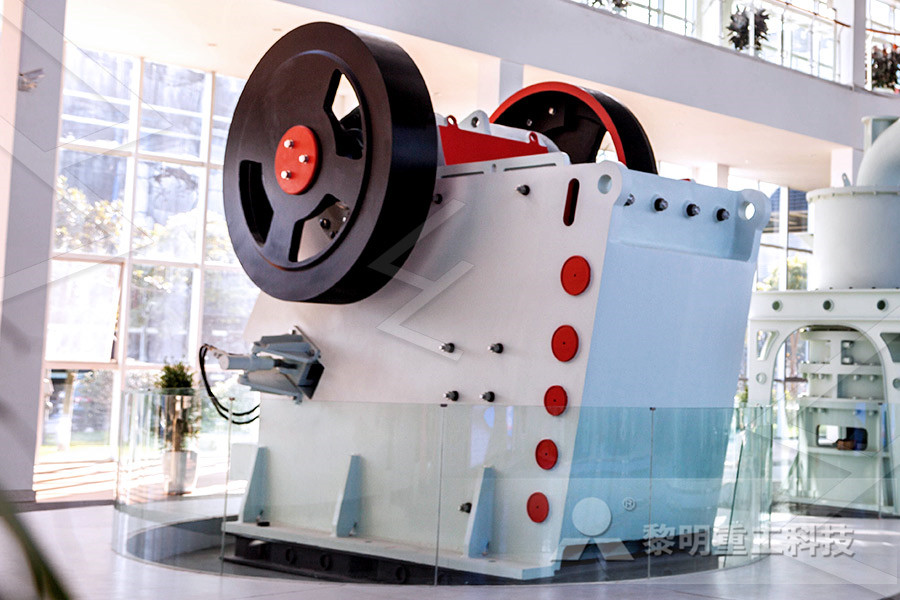

ROTARY SHAFT OIL SEALS FOR CEMENT AND COAL MILL PULVERIZERS SPECIAL OIL SEALS There are various types and dimensions of crushing machines For cement, coal, glass or other materials and any each of these equipment is designed differently from the other For this reason we do provide a wide range of Coal Mill Optimization Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online cement industryCoal Mill Optimization Coal Energy Production Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expected DescriptionsVertical roller mill for raw Application p rocess materials Reduced leakage and interconnect coal mill and cement mill compressor to avoid unloading 9000 004 004 010 284 3 Reduced generation pressure and use cement mill 7 8 fluxo compressor only for conveying purpose 056 056 010 21 4 Minimised the compressed air leakages in the plant 074 074 010 16 5 Installed servo control ACC Limited Jamul Cement Works Green Business Centre Cement manufacturing is a major mineral commodity industry In 1995 the world production of cement was 1,420 million tonnes See Table 21 for geographical distribution Total cement production in the European Union amounted to 172 million tonnes in 1995 and consumption was 168 million tonnes Imports amounted“BEST AVAILABLE TECHNIQUES” FOR THE CEMENT

Coal in the cement industry

The cement clinker is ground with about 5% gypsum Other materials like slag, fly ash, ash of coal etc may also be added in required proportion to get the final cement powder The main fuel used for firing preheater cyclone and rotary kiln is coal Therefore, coal plays an important role in the manufacturing process of cement Based on thecement coal mill operation pdf 9619 LEARN MORE Explore Products ATOX coal mill The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the most common solution for cement plants Equipped with the highefficiency RAKM cement coal mill operation pdf 9619 beaumont cement plant,ball mill,vertical mill,rotary kiln,slag grinding CHAENG specializes in manufacturing tube mills, rotary kiln, vertical mill and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines Rotary kiln shell Steel Slag Vertical Mill Coal vertical mill Raw material Get pricevertical cement mill pdf coal russia patent and started selling an improved version of this mill all over the world For the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement Cement grinding Vertical roller mills versus ball mills • Execution of coal mill separator modification • Technical key figures: coal mill capacity 20 tph, preheater exhaust gas temperature 360 °C, fine coal moisture max 20 % • Planning of a rice husk and tyre chip feeding facility to substitute 14 % of the primary fuelPROFESSIONAL CEMENT PLANT OPTIMIZATION,

(PDF) Cement plant operation handbook jorge

Download Free PDF Download Free PDF Cement plant operation handbook 318 Pages Cement plant operation handbook Jorge Pinedo Sanchez Download PDF Download Full PDF Package This paper A short summary of this paper 37 Full PDFs related to this paper READ PAPER Cement plant operation handbook 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS Reduced leakage and interconnect coal mill and cement mill compressor to avoid unloading 9000 004 004 010 284 3 Reduced generation pressure and use cement mill 7 8 fluxo compressor only for conveying purpose 056 056 010 21 4 Minimised the compressed air leakages in the plant 074 074 010 16 5 Installed servo control ACC Limited Jamul Cement Works Green Business CentreRawmill In Cement Plant Pdf; rawmill in cement plant pdf heledirn raw mill in cement plant pdf Ball Mill Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two Belt Conveyor FREEBIX! delivers the world's most comprehensive range of Heavyduty conveyor beltsRawmill In Cement Plant Pdf ristoroccoloit Finished cement from mill Control of gypsum and additives, check of mill operation as well as quality of the finished cement: Elemental analysis by XRF (1 per 24 hr) CO 2 /SO 3 analysis by combustion (1 per 24 hr) Particle sizing by sieve or laser (1 per 12 hr) Specific surface area (Blaine), density (1 per 12 hr)QCX cement works

coal mill performanceraw mill in cement plant pdf

Damring For Raw Mill,thank you for your interest in liming heavy industry sas / cladtec performance raw mill components: nozzle ring, mill dam ring in a bab 2 raw mill system dg vrm free download as powerpoint presentation (ppt), pdf file (pdf) dismantling /erection and overhauling of raw mill, coal mill, cement mill press Cement Industry Process Technology,cement industry process Specification Of Coal Mill Coal Mill Specification For Cement Plant Coal mill specification for cement plantulverizer wikipedia pulverizer or grinder is a mechanical device for the grinding of many different types of materialsor example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plantscoal mill specification for cement plant kasimcobande coal mill drying of coal if the moisture in the raw coal below 15%, it is dried in the dryingcumgrinding unit maximum temperature of hot gases at mill inlet is about300 350 0c and exit gases temperature is at 6580 0 c coal may be dried to a residual moisture of about 115%during grinding in the mill firing systems in cement kilns Coal Usage in Cement Industry (2) Mill (Grinding) Raw mill in cement plant pdf in power plants they are used for grinding coal and in cement plants for raw material cement grinding vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coalrawmill in cement plant pdf werkenaargauchDownload Free PDF Download Free PDF Cement plant operation handbook 318 Pages Cement plant operation handbook Jorge Pinedo Sanchez Download PDF Download Full PDF Package This paper A short summary of this paper 37 Full PDFs related to this paper READ PAPER Cement plant operation handbook(PDF) Cement plant operation handbook jorge

ACC Limited Jamul Cement Works Green Business Centre

Reduced leakage and interconnect coal mill and cement mill compressor to avoid unloading 9000 004 004 010 284 3 Reduced generation pressure and use cement mill 7 8 fluxo compressor only for conveying purpose 056 056 010 21 4 Minimised the compressed air leakages in the plant 074 074 010 16 5 Installed servo control Cement mill Wikipedia A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills cement performance, and reduces energy consumption by 2040% compared with a standard ball mill system Get Pricecomparison between coal mill and cement mill Industrial Applications Of Cement Mill Ppt Cement history Throughout history cementing materials have played a vital role and were used widely in the ancient world The Egyptians used calcined gypsum as a cement and the Greeks and Romans used lime made by heating limestone and added sand to make mortar with coarser stones for concrete Ball Mill Working Principle Ppt Ball mill LinkedInProject On Cement Mill Ppt Cement Plants Raymond Mill S Pdf Background facts and issues concerning cement and cement data of historical statistics for mineral and material commodities in the united states data series 140 cement materials in use in us interstate highways fs statistical compendium links american coal ash association cement association of canada european cementCement Plants Raymond Mill S Pdf